HORIZONTAL DRILLING

HDD Specialists

In our business there is a shortage of simple problems and even less simple answers. Directional drilling is an art. To steer a drill path 15 metres below the Southern Expressway and exit 180 metres away within a 2 metre exit envelope is not easy. This is what we do. Our extensive experience and resources time and again demonstrate we are up to the challenges that are presented by directional drilling projects.

Why Choose Us?

Horizontal drilling is an inherently complex endeavour with many variants to be considered on each project. Our proven ability to provide you a simple solution to complex problems stems from our wholesale approach to your project.

- We use a fully integrated drilling and electronics package to deliver the most accurate drilling management system.

- We plan each drill electronically in our planning stages of each drill prior to commencement on site.

- We have a comprehensive range of equipment to backup our drilling teams

Expertise & Specialisations

Installations

Multiple installations to 150 metres

Sizes

Sizes up to 900mm

Licensed

Licensed fusion and butt-welding

Detection

Locate underground services

Mine Site

Mine Site Compliant & Remote Works

Hydro Excavation

Safe and precise non-destructive digging

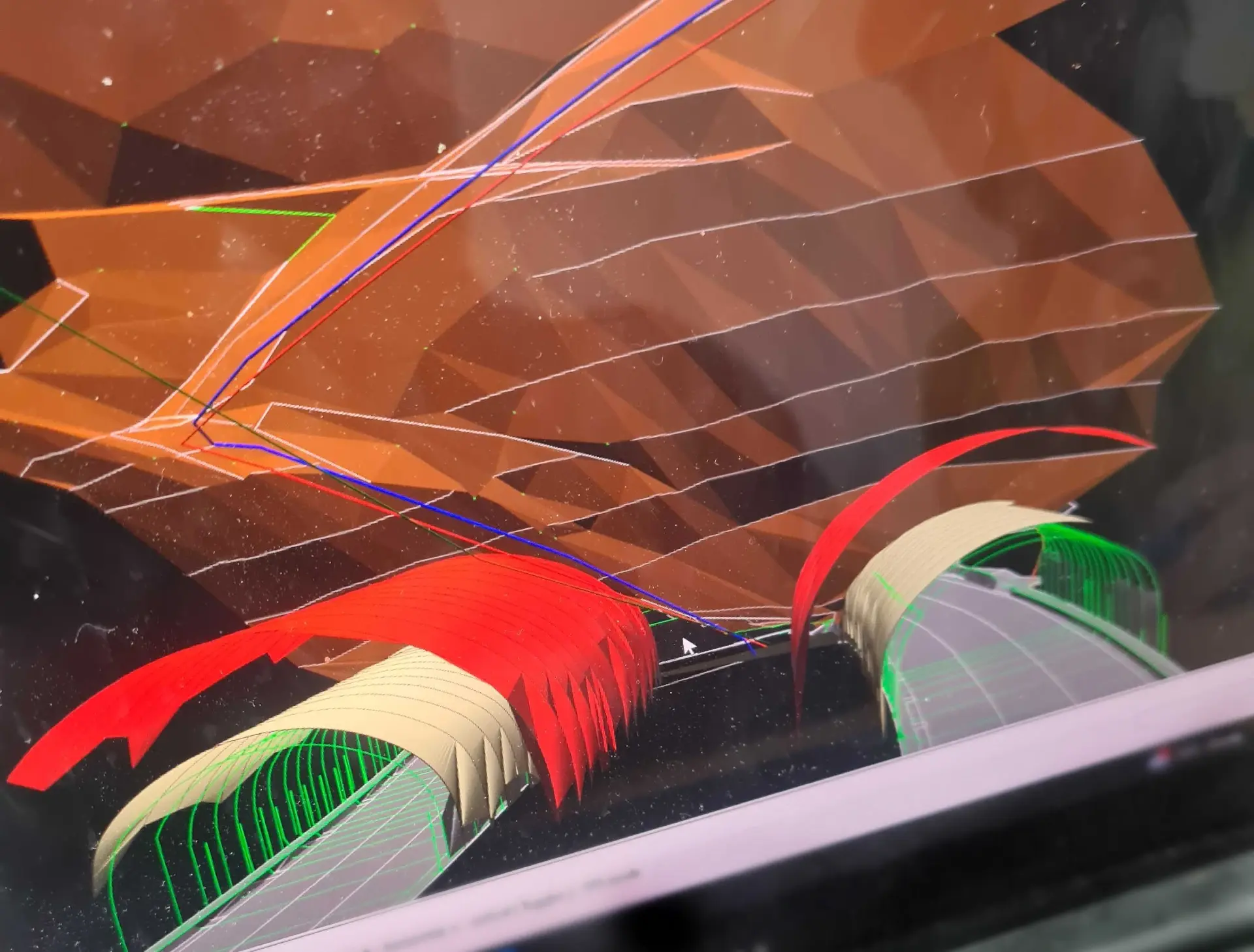

Advanced 3D Modelling

3 D Modelling is the most accurate means to design the required bore path, the model can be built up to capture all existing services within the area of works, calculate radial clearance zones for service within proximity to the proposed drill path. 3D Models are extremely accurate and build a comprehensive plan for complicated drills.

Bore designs for horizontal directional drilling (HDD) have various constraints that need to be carefully considered to design a drill path before construction. The length and path of the proposed bore is calculated considering various attributes such adjacent services, ground type such as soil type or rock.

Factors that need to be considered when designing a bore include:

- Depth of cover with respect to the final surface level, considering also the ground conditions.

- Depth of existing services located along the bore path and required clearance.

- The intended use of the bore –such as gravity, pumping mains or high pressure gas mains.

- The bend radius of the product pipe being steel or HDPE, reamers.

Quick Enquiry

What We Do

Services We Offer

What Clients Say

We dealt with Bench recently for some drilling work at our hotel, the staff were friendly, no mess or fuss Would highly recommend Bench, the price was right by a long way also!

Sue Westy